|

What Are You Looking For?

What Are You Looking For?

100% Servo-Driven Intelligence: Every critical axis – from unwinding and forming to cutting, folding, and stacking – is powered by precision servo motors. Eliminate mechanical transmission lag and enjoy unparalleled synchronization for flawless product consistency.

Industry-Leading Speeds: Achieve sustained production rates of up to 1200 diapers per minute (adjustable based on size/complexity), maximizing your output and ROI.

Ultra-Flexible Changeovers: Switch between diaper sizes, styles (tape-on, pant-type), and materials in minutes, not hours. Intuitive HMI recipes store settings for instant recall, minimizing downtime.

Pinpoint Accuracy & Quality: Servo control ensures micron-level precision in core forming, adhesive application, elastic placement, cutting, and folding, guaranteeing premium product quality batch after batch.

Significant Material Savings: Intelligent servo regulation optimizes material usage (topsheet, backsheet, SAP, elastics, tapes), drastically reducing waste and boosting your bottom line.

Reduced Maintenance & Downtime: Fewer mechanical components and wear parts compared to traditional machines translate to lower maintenance costs and higher overall equipment effectiveness (OEE).

Seamless Integration: Ready for Industry 4.0 with integrated data acquisition (OEE, output, waste tracking), remote monitoring capabilities, and compatibility with factory automation systems.

Brand :

FO-01Item No :

1Payment :

T/T,L/C,Western UnionProduct Origin :

ChinaColor :

CustomizedShipping Port :

XiamenLead Time :

180 daysMain parameters of the diaper-making machine

| Design Speed | 600 Pcs/min | Product Size | S, M, L, XL (Customized) |

| Stable Speed | 400-450 Pcs/min | Qualified Rate | ≥98% |

| Install Power | 380V 50HZ, Tri-phase | Machine Size | 30M*9.0M*4.5M |

| Power Supply | 250 KW | Weight | 80 Tons |

Main Function Features of Diaper Making Machine

1. Servo motor driving with PLC control and touch screen;

2. High-speed teeth-like crusher;

3. Web-wheel molding;

4. SAP auto adding with amount control;

5. Servo unwinding, auto-tension control and auto splicing for raw materials;

6. Auto reject for wasted products, auto detect & alarm for material exhausted;

7. Phase adjusting during running without stop

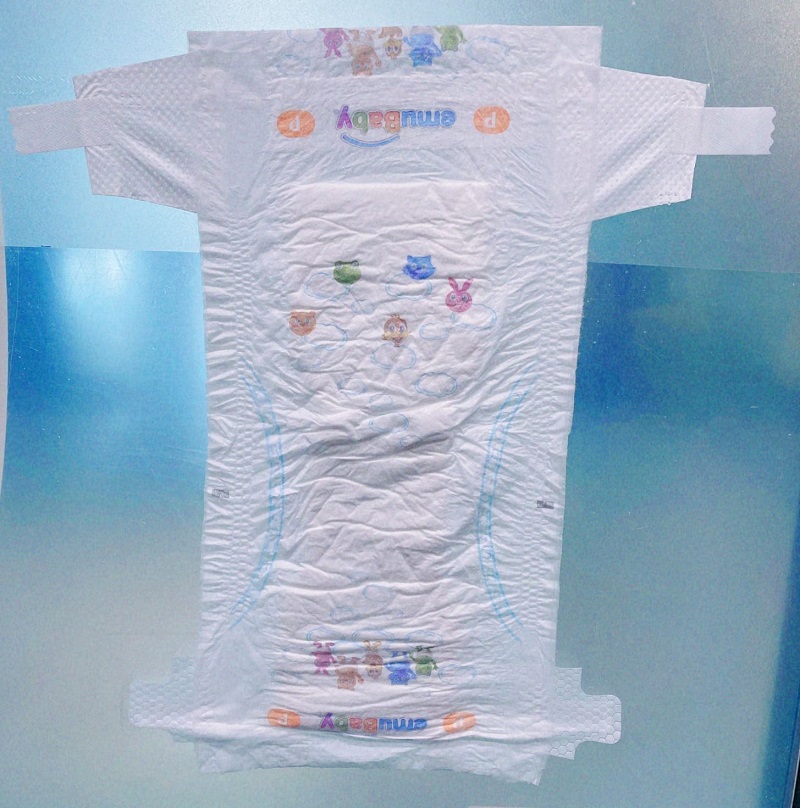

This servo-driven production line manufactures precision T-shape diapers with stable output at 400-450 pcs/min (design speed: 600 pcs/min). It guarantees ≥98% qualified rate and supports instant size switching between S/M/L/XL (customizable). Operating on 380V 50Hz tri-phase power (250 KW total), the machine measures 30m(L)×9m(W)×4.5m(H) with an 80-ton footprint.

Why Choose us?

Workshop

If you have interest in our product, pls feel free to contact us!

Tel: +86 -15859535393 Email: aria@firstonemachine.com