|

What Are You Looking For?

What Are You Looking For?

Core Formation: Fluff pulp is fiberized and mixed with SAP to form the highly absorbent core.

Lamination: The core is wrapped and combined with the top sheet and back sheet materials.

Elastic Attachment: Leg elastics and waistbands are applied. Advanced machines use ultrasonic bonding for a glue-free, soft waistband.

Shape Cutting & Sealing: The continuous web of material is die-cut into the final pants shape and the sides are sealed to form the pull-up design.

Folding & Packaging: The finished pull-ups are folded, stacked, counted, and automatically packaged.

Brand :

FOItem No :

FO-03Payment :

T/T,L/CProduct Origin :

ChinaColor :

CustmizedShipping Port :

Xiamen,ChinaLead Time :

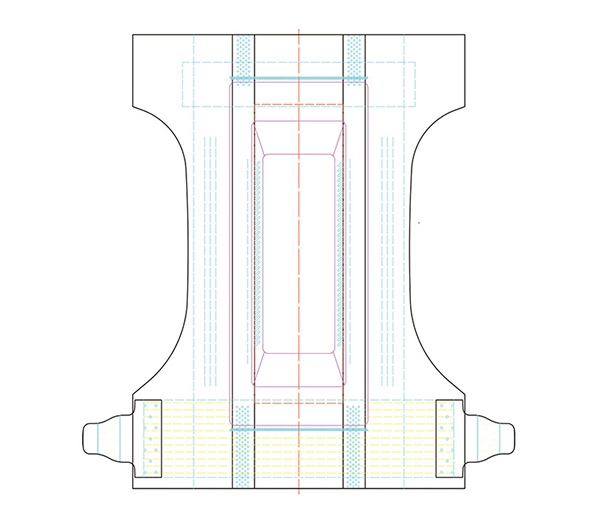

180 daysFull Servo I Shape Baby Diaper Making Machine

| Design Speed | 600 PCS/MIN |

| Stable Production Speed | 450PCS/MIN |

| Product size | S,M,L,XL |

| Machine size | 30m * 3m * 5m |

| Efficiency | >=88% |

| Air compressor | 0.6-0.8MPA |

| Rejection rate | <= 3% |

| Machine direction | Customerization |

| Machine weight | 60T |

| Operation area | 30m * 7m * 5m |

| Power source | 380V, 50HZ, 3 phase 8 wire |

| power | 280KW |

| Machine direction | Customerization |

Why Choose us?

Profession design

Our factory has in machinery industrials for 15 years,improve andinnovate technology from Japan Italy all the time.

Quality

All the spare parts used according to the contract, original German & Japan & Italy & USA brand.

Processing

CNC processing, special surface processing, anti-glue processing.

Commitment

We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

About First One

Quanzhou First One Machinery Co.,Ltd have more than 15 years experience focusing on hygiene machines.

Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on.

Turn-key service from start and its long life time service will be offered.

Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers.

Factory Processing Map

Packaging and Shipping

|

|

If you are interested in our machine, please feel free to contact us at any time!

Tel: +86 -15859535393 Email: aria@firstonemachine.com